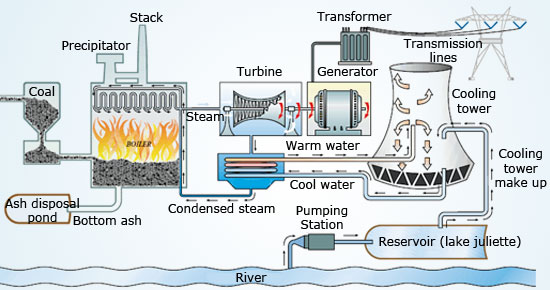

Coal from the mine is crushed, to a fine powder, mixed with air and blown into the boiler, or furnace for combustion. In the boiler the coal is fired and steam is produced. The high-pressure steam from the boiler, rich in energy, passes into the turbine (a massive drum with thousands of propeller blades). Once the steam hits the turbine blades, it causes the turbine to spin rapidly. The spinning turbine causes a shaft to turn inside the generator, creating an electric current.

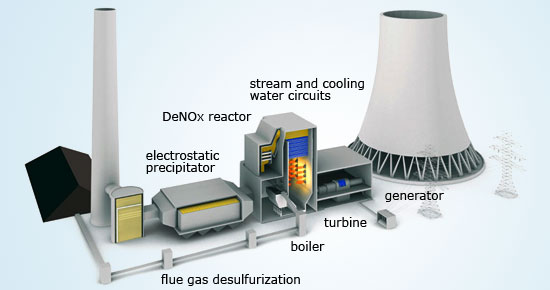

When coal is burnt, it produces carbon dioxide (CO2), sulphur dioxide (SO2) and nitrogen oxides (NOx). These flue gases are vented from the boiler. The incombustible components of the coal are released as bottom ash and fly ash. Bottom ash that fall to the bottom of the boiler is removed through a vent and the fly ash, which is very light, exits the boiler along with the flue gases. An electrostatic precipitator removes 99.4 per cent of fly ash before the flue gases are dispersed into the atmosphere.

The steam-water cycle in the power plant is a closed system: water vaporizes in the boiler; the steam expands in the turbine and then condenses in the condenser to water, which is returned to the boiler by pumps. In addition, there is a cooling water circuit: Cooling water is drawn into the plant and circulated through condensers, which cools steam discharged from the turbine. Steam from the turbine also passes through the condensers in separate pipes from cooling water.The cold water is warmed by the steam,which condenses back into pure water and circulates back to the boiler to begin the process of generating electricity again.